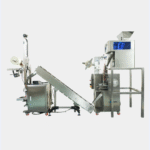

Pyramid Tea Bag Packing Machine with Outer Sachet

Short Description

Pyramid tea bag machine with outer sachet for premium packing.

Businesses We Serve

Material Input

Tea or Herbal Blend (in leaf, granule form)

Material Output

Pyramid-shaped tea bags with optional outer sachet

Certifications:

Product Output:

Produces pyramid-shaped tea bags that allow tea leaves to expand fully for optimal infusion, with outer envelope packaging. Perfect for premium and herbal tea products.

Packing premium pyramid tea bags for whole leaf, herbal, and specialty teas with optional outer sachet for presentation and export.

- Food-grade nylon or PLA mesh bags

- Ultrasonic sealing for premium quality

- Adjustable fill weight

- Outer sachet attachment optional

- Compact design with PLC touchscreen

- Minimal maintenance

- Nylon, PLA Roll with attached tags for ultrasonic seal

- Outer Envelope Film: Heat-sealable laminated material (Paper / PET / Aluminum Foil / PE) / Poly Coated Paper Roll, ensuring freshness and aroma protection & leakage proof.

Technical Specifications

| Production Capacity: | 30–35 bags/min |

|---|---|

| Standard: | Tea Bag Size Standard: 60 mm x 60 mm Sachet Size Standard: 90 mm x 75 mm (Customized) Tag Size Standard: 20 x 20 mm (Customized) Thread Standard: 110-135mm (Customized) |

| Filing Volume Range: | 1.5–2.5 g (Customized) |

| Type of Film: | Nylon / PLA mesh + outer envelope laminate |

| Sealing Type: | Ultrasonic |

| Filling Type: | Weighing |

| Voltage Supply: | 220V AC / 50Hz (Customized) |

| Power Requirement: | 5 kW |

| Air Pressure: | 6 Bar |

| Air Consumption: | 5.6 CFM |

| Machine Dimensions (LxWxH in mm): | 2000 x 2500 x 3500 mm |

| Weight: | 525 kg |

| Material of Construction: | SS304 & Food Grade Material |

Operational Details

| Operator Requirement: | 1 skilled operator |

|---|---|

| Setup Time: | 15–20 minutes |

| Noise Level: | <65-70 dB |

| Power Backup: | Compatible with UPS / Generator |

Performance & Output Details

| Production Output / Shift: | Up to 16,200 bags per 8-hour shift (Actual Production) |

|---|---|

| Accuracy / Tolerance: | ±0.2 g |

| Downtime / Efficiency%: | 96% uptime |

| Sample Product Image / Video: | Available on request |

Commercial & User-Oriented Info

| Pre-Dispatch Inspection (PDI): | Buyer or authorized representative may inspect the machine before dispatch. Detailed test run videos and reports will be shared for approval prior to shipment. |

|---|---|

| After-Sales Support: | Expert installation, on-site training, and prompt remote assistance via video call or email. |

| Spare Parts Availability: | Available In stock |

| Lead Time / Delivery: | Lead Time / Delivery: 6–8 weeks (delivery may vary depending on machine type and specifications) |

| Warranty Period: | 12 months (excluding any damage caused by the operator or accidental mishandling). |

| Packaging & Shipping Details: | Machines are securely packed in export-grade wooden crates or pallets, ensuring safe international shipment by sea or air freight. |

| Freight & Insurance: | To be borne by the buyer unless otherwise agreed (FOB / CIF / DDP terms can be discussed). |

| Payment Terms: | 30% advance, 70% before dispatch |

| Installation & Commissioning: | Provided |

| Notes: | 1- The machine carries a 12-month warranty from the date of dispatch against manufacturing defects (excluding wear-and-tear parts). 2- Any electrical or mechanical fault arising from misuse, poor maintenance, or use of non-original parts is not covered under warranty. |

Get in Touch

Looking to start or scale your tobacco or nicotine pouch production line?

📞 Contact SidSam Group today to explore customized, automated and cost-efficient tobacco machinery solutions.