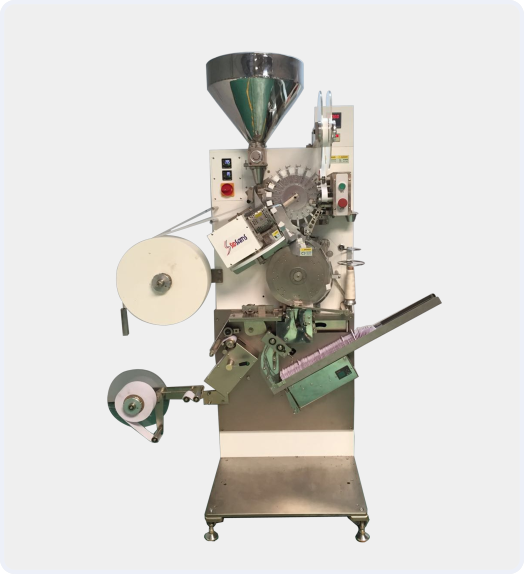

Single Chamber High-Speed Tea Bag Packing Machine with Paper Crimping Outer Envelope

Short Description

High-speed tea bag machine with paper crimping outer envelope.

Businesses We Serve

Material Input

Tea or Herbal Blend (in leaf, granule or powder form)

Material Output

Tea Bag with String & Tag Individually Packed in Paper Crimping Outer Envelope

Certifications:

Product Output:

Produces single-chamber tea bags with paper-crimped envelopes, maintaining uniform filling and premium presentation. Ideal for high-volume production and retail packing.

Single chamber tea bag packing with paper crimp sealing for eco-friendly outer envelopes.

Paper crimp-sealing technology for sustainable packaging Automatic thread & tag feeding Adjustable bag size & fill weight PLC control with touchscreen Stainless steel food contact parts Compact design and low maintenance

Filter Paper: Heat-sealable food-grade filter paper for inner tea bag Thread: Natural cotton thread for tag attachment Tag Paper: Printed paper tag for branding or labeling Outer Envelope Film: Poly Coated Paper Roll, ensuring freshness and aroma protection & leakage proof.

Technical Specifications

| Production Capacity: | 100-150 bags/min |

|---|---|

| Standard: | Tea Bag Size Standard: 50 mm x 50 mm Envelope Size Standard: 65 mm x 70 mm Tag Size Standard: 20 x 20 mm (Customized) Thread Standard: 110-135mm (Customized) |

| Filing Volume Range: | 1.5–2.5 g (Customized) |

| Type of Film: | Filter Paper / Lamination |

| Sealing Type: | Heat Sealable Sealing |

| Filling Type: | Volumetric |

| Voltage Supply: | 220V AC / 50Hz (Customized) |

| Power Requirement: | 4.2 kW |

| Air Pressure: | 6 Bar |

| Air Consumption: | 5 CFM |

| Weight: | 525 kg |

| Material of Construction: | SS304 & Food Grade Material |

Operational Details

| Operator Requirement: | 1 skilled operator |

|---|---|

| Setup Time: | 15–20 minutes |

| Noise Level: | <65-70 dB |

| Power Backup: | Compatible with UPS / Generator |

Performance & Output Details

| Production Output / Shift: | Up to 47,000 bags per 8-hour shift (Actual Production) |

|---|---|

| Accuracy / Tolerance: | ±0.2 g |

| Downtime / Efficiency%: | 96% uptime |

| Sample Product Image / Video: | Available on request |

Commercial & User-Oriented Info

| Pre-Dispatch Inspection (PDI): | Buyer or authorized representative may inspect the machine before dispatch. Detailed test run videos and reports will be shared for approval prior to shipment. |

|---|---|

| After-Sales Support: | Expert installation, on-site training, and prompt remote assistance via video call or email. |

| Spare Parts Availability: | Available In stock |

| Lead Time / Delivery: | Lead Time / Delivery: 6–8 weeks (delivery may vary depending on machine type and specifications) |

| Warranty Period: | 12 months (excluding any damage caused by the operator or accidental mishandling). |

| Packaging & Shipping Details: | Machines are securely packed in export-grade wooden crates or pallets, ensuring safe international shipment by sea or air freight. |

| Freight & Insurance: | To be borne by the buyer unless otherwise agreed (FOB / CIF / DDP terms can be discussed). |

| Payment Terms: | 30% advance, 70% before dispatch |

| Installation & Commissioning: | Provided |

| Notes: | 1- The machine carries a 12-month warranty from the date of dispatch against manufacturing defects (excluding wear-and-tear parts). 2- Any electrical or mechanical fault arising from misuse, poor maintenance, or use of non-original parts is not covered under warranty. |

Get in Touch

Looking to start or scale your tobacco or nicotine pouch production line?

📞 Contact SidSam Group today to explore customized, automated and cost-efficient tobacco machinery solutions.